-

Floor Safety Signs - Area In Front Of Electrical Panel Must Be Kept Clear

$28.39

$27.09

Supplied in: Each -

BelTrac® Wall-Mount Retractable Belt 55-5550/SA/FY

$1,011.79

$738.39

Supplied in: Each -

Kanban Cards

$124.79

$93.59

Supplied in: Pack of 50 Tags -

Beltrac Magnetic Wallmount Retractable Belts - Please Do Not Enter

From $166.39 To $251.39

From $124.79 To $244.39

Supplied in: Each -

Beltrac Magnetic Wallmount Retractable Belts - Blank

From $114.39 To $140.39Supplied in: Each -

Beltrac Magnetic Wallmount Retractable Belts - Caution

From $192.19 To $193.99

From $124.79 To $166.39

Supplied in: Each -

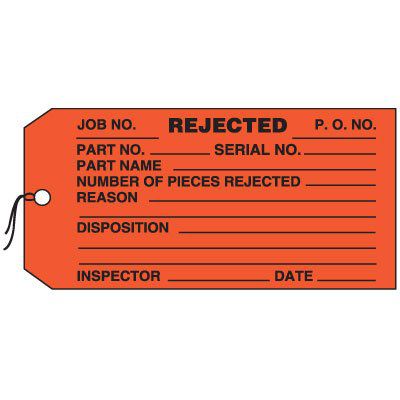

Production Status Tags - Rejected

$1.79

$0.69

Supplied in: Each -

IRONguard™ MagTool Clipboard for Forklifts

$49.99

$41.59

Supplied in: Each -

Bilingual Warning Forklift Traffic Floor Stencil Pavement Tool S-5516 D

$51.99Supplied in: Each -

Floor Stencils - Garbage Can

$57.19

$51.99

Supplied in: Each -

Floor Stencils - Fire Extinguisher

$57.19

$51.99

Supplied in: Each -

Shop Floor Control Cones

$12.49

$9.39

Supplied in: Each -

High Visibility Overhead Signs - Pallet Storage Area

From $91.99 To $135.89

From $58.29 To $70.69

Supplied in: Each -

High Visibility Overhead Signs - Receiving With Left Arrow

From $91.99 To $222.89

From $58.29 To $112.29

Supplied in: Each -

Shadow Board Tool Tape

$60.99Supplied in: Roll of 12 Feet -

Caution Watch Step Anti-Slip Tape Nadco ASV-2CWS

$62.39

$34.39

Supplied in: Roll of 60 Feet -

Maintenance Tags - Out Of Service

$29.39

$8.39

Supplied in: Pack of 25 Tags -

Floor Stencils - Do Not Block

$57.19

$51.99

Supplied in: Each -

Bilingual Keep Aisle Clear Floor Stencil

$51.99Supplied in: Each -

Chock Wheels Before Floor Stencil Pavement Tool S-5529 D

$51.99Supplied in: Each -

High Visibility Overhead Signs - Shipping With Right Arrow

From $102.39 To $222.89

From $68.69 To $112.29

Supplied in: Each -

Warning Anti-Skid Tape - Caution Watch Your Step

$121.28

$26.87

Supplied in: Roll of 54 Feet -

Maintenance Tags - Hold

$29.39

$8.39

Supplied in: Pack of 25 Tags -

Semi-Custom Red Tag Area Sign

From $76.69 To $104.29Supplied in: Each -

Red Tag Area Signs - 5S Red Tag Area Label All Items

From $82.29 To $109.89

From $62.39 To $93.59

Supplied in: Each -

Clear Floor Tape Labels - Incoming Goods

$14.49

$6.79

Supplied in: Each -

Clear Floor Tape Labels - Finished Goods

$14.49

$6.79

Supplied in: Each -

Clear Floor Tape Labels - Garbage

$14.49

$6.79

Supplied in: Each -

Clear Floor Tape Labels - Pallet Jack

$14.49

$6.79

Supplied in: Each -

Clear Floor Tape Labels - Work In Process

$14.49

$6.79

Supplied in: Each -

Custom Bulk Arrow Signs

$54.19Supplied in: Pack of 5 Each -

Electrical Panel Floor Stencil Pavement Tool S-553102

$51.99Supplied in: Each -

Floor Safety Signs- No Smoking Graphic

$52.19

$25.99

Supplied in: Each -

Out of Service Production Status Tags

$1.79

$0.69

Supplied in: Each -

Warning Anti-Skid Tape - Authorized Personnel Only

$121.28

$26.87

Supplied in: Roll of 54 Feet -

Warning Anti-Skid Tape - Black/Yellow Striped

$121.28

$26.87

Supplied in: Roll of 54 Feet

Visual Workplace

Find everything you need to get started with your Kanban / Lean Manufacturing program, including all the tools you need to initiate a red tag system to remove waste from your facility. View our Lean 5S Product Selection Guide here.

The ideology behind Lean Manufacturing is to create a set of techniques that eliminate waste and enhance business performance. The system focuses on getting waste out of the supply chain. One way to do this is to use the red tag system. The idea is that red tags are applied to products or items that are no longer necessary and need to be removed. Kanban stations and tags can also help with organization.

Lean Manufacturing also incorporates the 5S system, which uses visual aids to reinforce standards and highlight abnormalities. In order to achieve this, first place a border around items to designate a home. Then, place a label inside the border and a corresponding label on the product to make it easy to match the item with its home. The 5S system also advises the use of floor marking tape to indicate the proper flow of materials around your facility.